Novel Foods To Save The Planet

Exciting scientific innovation is reshaping the future of one of the most ubiquitous human passions and most polluting industries — food

Words by Silvena Ivanova

“Food production is ripping the living world apart. Fishing and farming are, by a long way, the greatest cause of extinction and loss of diversity and abundance of wildlife. Farming is a major cause of climate breakdown, the biggest cause of river pollution and a hefty source of air pollution,”

says George Monbiot, British environmental journalist, activist and author of Regenesis: Feeding the World without Devouring the Planet

A solution to all of these issues is taking root in the innovative fields of cellular agriculture and precision fermentation. Both are the domains of a new, rather unexpected kind of food producer: scientists, microbiologists and biotech researchers, who are ‘farming’ food on a microscopic level, often from single-cell organisms rich in proteins and underexplored benefits. Their methods sidestep the environmental pitfalls of traditional agriculture, such as extensive land, feed and water use, and the industry's significant greenhouse gas contributions, which account for approximately 25 to 35% of global emissions. Here, we spotlight a few pioneers from this emerging wave of food entrepreneurs poised to transform our culinary landscape.

(Above) Meticulously monitored precision fermentation process at Formo’s laboratory in Berlin.

A protein made out of thin air

Images by Solar Foods

Solein is an animal-free, plant-free protein made through a process of gas fermentation (not unlike the brewing of beer or kombucha) in which single-cell microbes are cultivated using carbon dioxide and electricity. According to Solar Foods, the Finnish food-tech company behind it, the main ingredients their microbes ‘feed’ on are carbon, hydrogen, oxygen and nitrogen, all of which can be captured from the air — explaining both their catchy marketing slogan ‘protein made out of thin air,’ and disruptive potential. “We want to fundamentally disconnect from land use, from agriculture, that’s the reason why we are here,” says Pasi Vainikka, Solar Food’s co-founder and CEO. “And when you do that, many of the environmental benefits also fall into your lap.” Solein is produced using electricity from renewable sources, and its footprint including land, energy, water and feed is only a tiny fraction compared to farmed animal- or plant-based foods.

“We want to fundamentally disconnect from land use, from agriculture, that’s the reason why we are here”

The nutritional benefits of this eco-friendly protein also make a strong case — it’s much lower in fat than meat or dairy, yet contains all of the essential amino acids, along with iron, fibre and vitamin B. It comes in the form of a flour-like yellow powder, which can be used either as raw material to make various food products, or as a cooking ingredient in itself. Enough promise to pique the interest of creatively minded chefs.

Michelin-starred chef Mirko Febbrile and his Italian restaurant Fico in Singapore were among the first to embrace the innovative ingredient. “It has a nutty and buttery profile, with hints of sweetness,” says Febbrile. “The taste reminds me of carrots and the umami richness of mushrooms, particularly porcini. It's a versatile ingredient that can be incorporated into both sweet and savoury dishes.”

This was an inspiration for him and another sustainably minded chef, Oliver Truesdale-Jutras, to jointly develop a 5-course tasting menu exploring the yellow powder’s potential. From Italian favourites such as fresh pasta and chocolate gelato to more local, seasonal exporations, their creative collaboration made the pioneering air-protein menu a success with the first lucky diners involved in the trial. But their primary motivations to endorse Solein have more to do with its sustainable nature — Febbrile explains that he is eager to challenge preconceived notions about food, and encourage a shift towards more environmentally friendly ingredients. “Why can't we change the game in that sense? If we can make Solein a part of daily meals, it will truly revolutionise our approach to food consumption.”

How far do we stand from that prospect today? Solein has already been approved as novel food in Singapore, where it is about to become more widely available. It is still awaiting approvals from the EU, UK and US food regulators, with the ambition to embark on these markets next. Meanwhile, Solar Foods are preparing to open Factory 01, their first large-scale production facility near Helsinki, set to launch later this spring. The new factory, along with some strategic partnerships with global food producers, are on course to bring this futuristic protein closer to the daily reality of restaurants and supermarkets. We can’t wait.

“If we can make Solein a part of daily meals, it will truly revolutionise our approach to food”, says Michelin-starred chef Marco Febbrile

Creating cheese from microbes

Images by Formo & Luke Johnson

Reportedly, many conscientious eaters (largely, but not solely vegetarian) admit that the main reason for not embracing veganism is the pain of renouncing the pleasures of cheese. Although plant-based alternatives have become much more widely available in the last decade, their popularity is incomparable, as they struggle to match the versatile flavours, textures and palatability of the dairy original. And flavour isn’t the only challenge. People often describe their love for cheese in emotional terms — casein (a protein found in cheese) is known to stimulate this addictive response, enhancing feelings of wellbeing and pleasure.

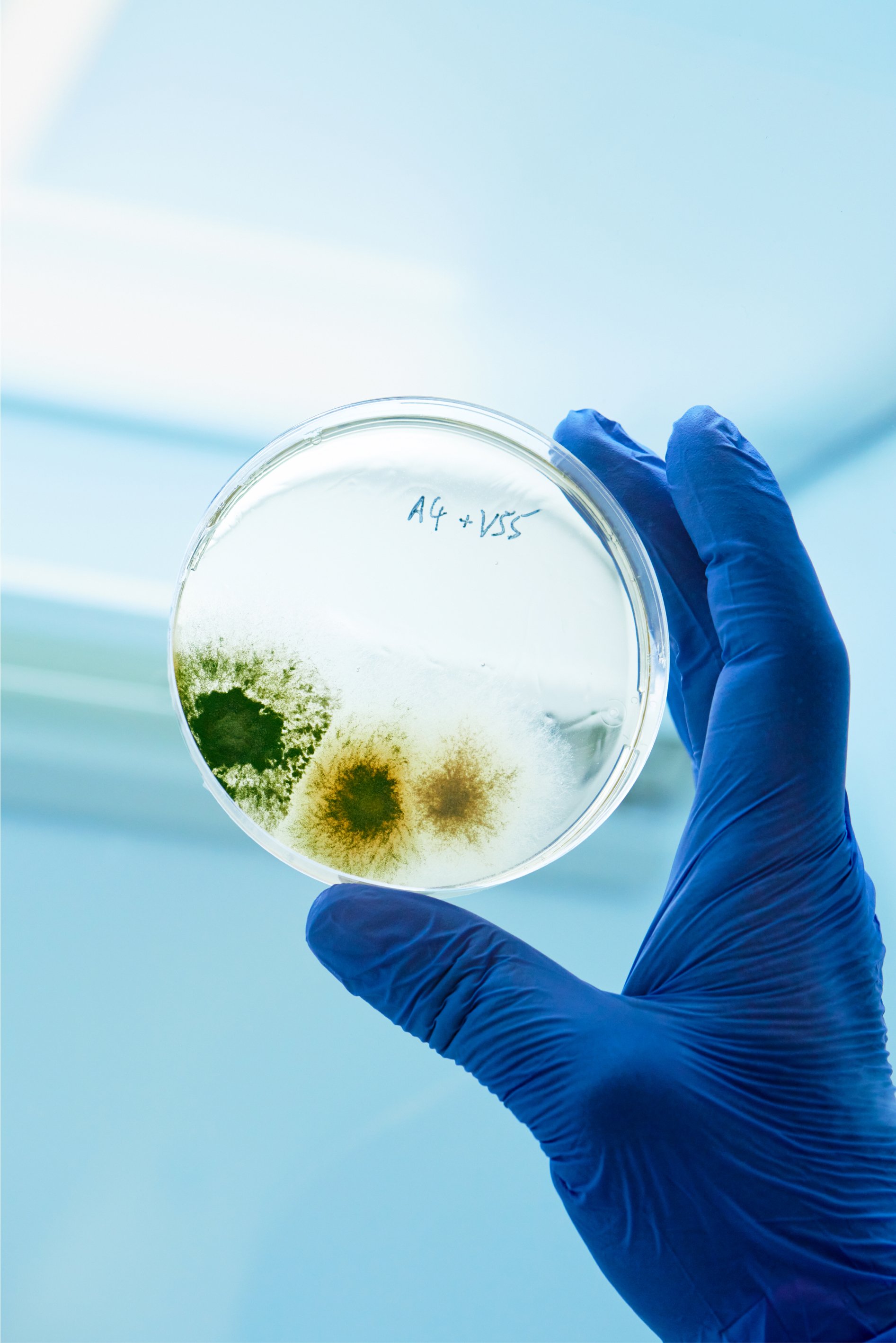

Against these odds, does animal-free cheese stand a chance? The answer could be found in the lab. More specifically, in precision fermentation — the process of growing microorganisms to produce complex organic molecules under controlled conditions. This is not new knowledge, precision fermentation has already been in use for decades in the production of insulin, vaccines and food supplements, among others. Now it’s regaining popularity for its capacity to reproduce proteins such as casein, and ultimately… to revolutionise the dairy industry.

This is the exact ambition of Formo, a food-tech innovator based in Berlin, and the first in Europe to come up with a range of cheeses made from microorganisms. With plausible names such as Frankoforte, Le Berg and Hellasdorf, their debut collection — including fresh spreads, soft, aged and blue cheese varieties — sounds reassuringly ‘real’. Now, they are about to face the ultimate test. “This is a pivotal moment for us, Formo’s marketing director Victoria Reinsch tells Looms. “We're on the cusp of introducing our products to the market, with initial offerings already making their way to select gastronomy partners in Germany.”

“We use less land, less water, we have less greenhouse gas, it’s much more efficient, and we don’t have the animal in the process. Not only is it more sustainable but also, it eliminates concerns around ethical farming and health.”

Formo’s young and eloquent Brazilian-Swiss founder, Raffael Wohlgensinger is a cheese aficionado on a quest to tackle the negative impact of dairy farming in particular. “When we look at how food is produced and distributed today, it’s completely different from the positive emotions and memories we have around food,” he argues. “We’ve built a system around it which is extractive, pressure-driven and not caring at all. The message is very clear. We have these products that we’re emotionally connected with, but a system that’s reaching its limits, so we have to drastically reduce our dependencies on animals to produce these products.”

When it comes to the benefits of precision-fermentation dairy, his message is equally clear. “We use less land, less water, we have less greenhouse gas, it’s much more efficient, and we don’t have the animal in the process. Not only is it more sustainable but also, it eliminates concerns around ethical farming and health.”

The only hurdle left to overcome is to convince emotional consumers of this sensible trade-off. Formo stays positively realistic. “Changing perceptions is always a challenge, but it's one we embrace with open arms,” says Reinsch. “It's about showing that animal-free dairy products can stand on their own and offer a new, exciting experience that's both familiar and novel.”

Seafood that doesn’t touch the ocean

Images by Wim Jansen & Anna Brauns

According to the UN's Food and Agriculture Organization, 157 million tonnes of fish a year are caught for human consumption, pushing 90% of the world's fish stocks to the brink of maximal exploitation or overfishing. This intensive fishing not only depletes oceanic populations, but also wreaks havoc on marine ecosystems through pollution, loss of biodiversity and habitat destruction. The simplest remedy seems to be eliminating fish from our diets altogether. Unless… Cellular agriculture may soon be offering an accessible way to alleviate the oceans without leaving fish off our plates.

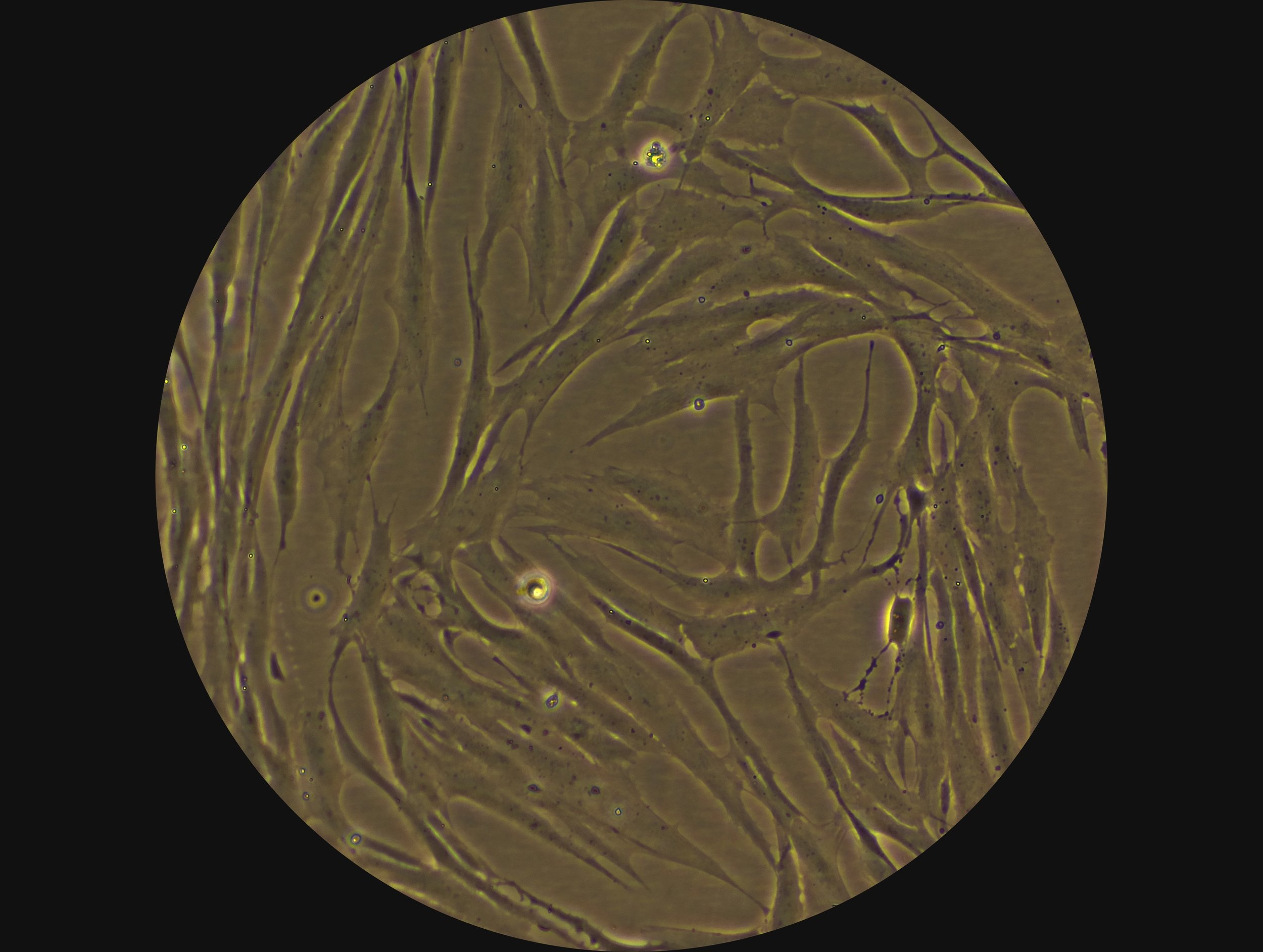

“We can make an important contribution to the supply of animal protein that allows us to manage our oceans in a sustainable way,” says Dr Sebastian Rakers, a marine biologist, biotech researcher and the co-founder of Bluu Seafood. In 2020, together with Simon Fabich (a business strategist with a track record in sustainable food innovations), Rakers started up Europe's first company for cell-based fish. Their plan is to enter the market cautiously, while continuous research and development are underway. “We wanted to start with products that are still hybrid, that is, they consist mostly of fish cells, but together with plant components — such as fish balls and fish fingers. The goal is of course to end up with a whole fish fillet on the plate,” says Rakers.

“Cultured fish can be produced wherever it is to be eaten, regardless of access to the sea. In addition, only what is needed and used is produced”

With research laboratories based in the North-German town of Lübeck, Bluu’s team of scientists is cultivating fish stem cells in a process that is controlled and precise, yet free from genetic engineering. “Cell growth in the fermenter follows natural processes, just like the cells would grow in a living fish,” Rakers explains. “Cell mass is created from muscle cells, fat cells and connective tissue cells, which doesn’t differ from real fish in terms of taste and cooking behaviour.” The added value lies in its sustainability. “Cultured fish can be produced wherever it is to be eaten, regardless of access to the sea. In addition, only what is needed and used is produced. Of course, we also need energy for this, but we take that requirement into account when planning the factory and want to develop a holistic production process including renewable sources.”

As is often the way for food pioneers, Bluu Seafood’s forward pace is tempered by official regulators, and approvals are slow to come through. But the German entrepreneurs believe they are well on track to get their first market approval in Singapore within 2024, followed by the US in a year’s time. They are not alone. Similar cultured fish start-ups, such as California-based Finless Foods, are also in the race to win over the US Food and Drug Administration (FDA) and American consumers with vegan propositions. Finless are notable for their focus on tuna, boldly challenging the unethical supply chain of the most consumed fish in the world with their first of its kind lab-grown alternative.

For their latest updates, follow @solar_foods; @eatformo; bluuseafood.